MaxFil™ Pressure Filtration Device

|

The MaxFil™ Pressure Filtration Device now has a Teflon®-coated aluminum design which is durable and lightweight. The MaxFil is specifically designed to meet the demands of the Toxicity Characteristic Leaching Procedure. Design features built into this hazardous waste filtration system make complying with Method 1311 easy and efficient. No splitting of the sample extract is necessary because the 2200mL capacity allows the analyst to load the entire sample before filtration begins. This not only saves time but also reduces the supplies necessary to prepare a sample. Pressurization is achieved by use of a quick connect fitting instead of a cumbersome hose-barb fitting. This quick-connect requires no clamping and, unlike a barbed fitting, it cannot "blow off" during filtration. All pressures are monitored by a pressure gauge located on the top plate of the MaxFil. When used with a regulator, filtration can be performed accurately and precisely without constant attention by the analyst. Sample materials may be introduced into the MaxFil by removing the top plate or through the 1" diameter entry port. This unique entry port has a two-inch knurled handle that enables any analyst to open and close the port without the use of tools. All wetted surfaces of the Maxfil are Teflon®-coated to offer extra assurance that no leaching of metals will occur. | |||

|

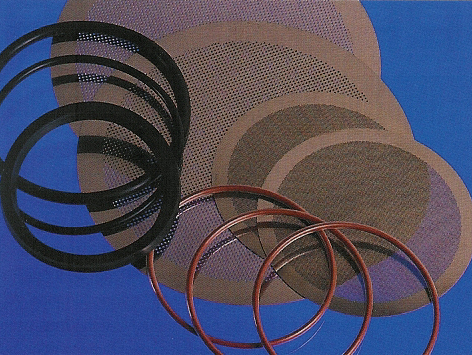

| O-ring sets, 316SS photoetched screens and quality replacements parts. All parts made of approved materials. |  |

Pressure Filtration Accessories |

Catalog Number |

Filter support screen, 316 stainless steel |

PSS142MM |

Teflon-coated Filter support Screen |

PSS142MM-T |

Plate O-ring, Viton™ |

PVR000-2 |

Inlet O-ring, Viton |

PVR100-1 |